Technological

Technological Developments in Processing Palm Oil Mill Liquid Waste (POME)

August 14, 2023

Palm oil mills are one of the industries that produce significant liquid waste, known as palm oil liquid waste (POME – Palm Oil Mill Effluent). POME contains organic materials, fats, nutrients and dangerous substances which can pollute the environment if not processed properly.

In the last few decades, technological developments in processing palm oil mill wastewater have become the main focus to reduce its negative impact on the environment. The following are some of the technological developments that stand out in the processing of palm oil mill wastewater:

Biological

Biological technology, or biology, uses microorganisms such as bacteria and fungi to break down organic materials in liquid waste into simpler and less dangerous materials. One of the commonly used methods is aerobic and anaerobic processing. Aerobic processing involves the use of oxygen by microorganisms to decompose organic matter, while anaerobic processing is carried out in conditions without oxygen. This method produces activated sludge or biogas which can be reused or converted into an energy source.

Biogas

One of the results of the anaerobic processing process is biogas, which is a mixture of methane gas (CH4) and carbon dioxide (CO2). Biogas can be used as an environmentally friendly alternative energy source. The biogas production process from liquid waste from palm oil mills involves methanogenic bacteria which decompose organic material into methane gas. Biogas can be used to produce electricity and heat, reducing dependence on fossil energy sources.

Evaporation

Another POME processing method is evaporation. In this method, POME is heated to a certain temperature to evaporate the water contained in it. This process produces condensate and concentrate. Condensate can be reused in the production process, while concentrate contains higher levels of organic matter. The concentrate can then be further processed through other methods such as biological processing or used as organic fertilizer. Evaporation is an effective method in reducing POME volume and producing high-value by-products.

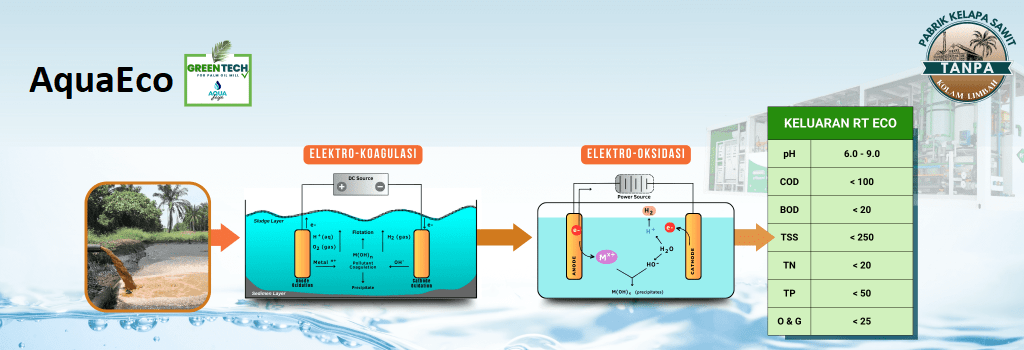

Electrochemistry

Recent developments in POME processing involve the use of electrochemical methods. This method involves the use of electrodes and electric current to oxidize the organic substances in POME into simpler and safer compounds. Electrochemical processes can produce useful byproducts such as hydrogen and oxygen. In addition, the electrochemical method has advantages in terms of energy efficiency and does not require additional chemicals and the resulting waste gas does not contain toxic elements or dangerous pollutants. This is different from several other waste processing methods which can produce dangerous gas emissions, so this method is recommended because it is more effective and more environmentally friendly.

In facing increasing environmental challenges, the palm oil industry is expected to continue to strive to develop more sustainable technology in processing its liquid waste. By using the right technology, palm oil mills can reduce negative impacts on the environment, such as greenhouse gas emissions. Apart from that, processing palm oil factory waste can also provide economic benefits, such as the production of biogas, compost, biochar and animal feed.

Thus, choosing the best technology to process palm oil mill waste is an important step in maintaining the balance of social, economic and environmental aspects in the palm oil industry and palm oil mills can contribute to global efforts to preserve the environment.